Modern testing equipment for maximum safety and high standards

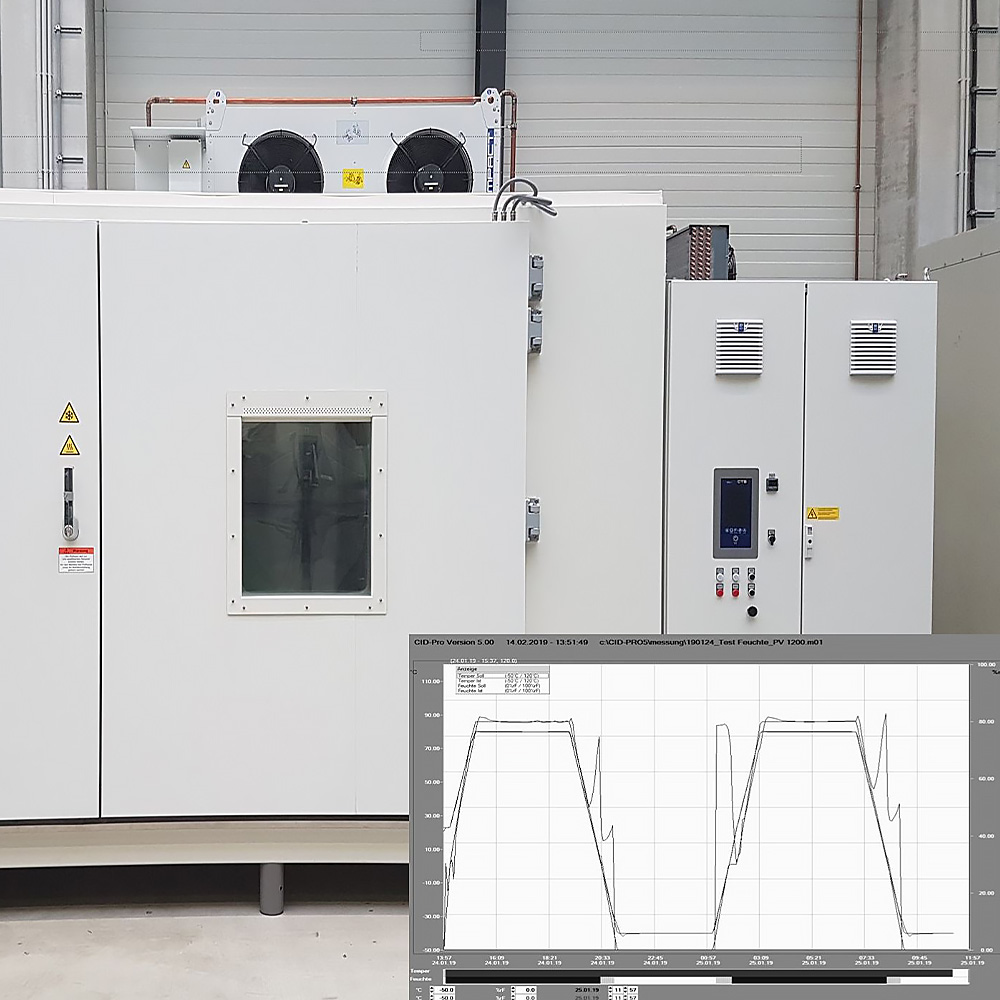

To ensure the high quality standards of the components produced, the specialist laboratories of LMS analyze material samples and surfaces at each location on a daily basis. We have extensive testing equipment: for example, a heating furnace, four climatic chambers with up to 22m³ volume, stiffness test stands or cold impact pendulums. In addition, we use 3D photogrammetry systems, 3D scanning systems, steam jet test chambers, stone chip test systems, microscopes for coating thickness measurements, color and wavescan measuring devices and a Willing light studio for visual color evaluation.

Maximum safety is important to us in every laboratory test and in all facilities. To achieve this, we test prototypes according to the required testing protocols and approval procedures, such as PPAP. At the same time, we ensure the durability of the final product manufactured.

Our technology

Test procedures we perform

- Climatic chamber CTS CW-55/22 Test chamber volume 22m³ -55°C to +140°C, 10% to 95% relative humidity

- Climatic chamber CTS CW-40/15 Test chamber volume 15m³ -40°C to +130°C, 10% to 95% relative humidity Climatic chamber CTS CW-50/5

- Test chamber volume 5m³ -50°C to +130°C, 10% to 95% relative humidity

- Heating furnace GFO Test chamber volume 8m³ +50°C to +150°C

- Climate chamber Vötsch C1500 Test chamber volume 1.5m³ -40°C to +180°C, 10% to 95% relative humidity

- Stiffness test rig Force application with 2 cylinders up to 5 KN

- Cold impact pendulum impact speed from 2,2-11,2 km/h

- 3D photogrammetry with Aicon system

- 3D measuring machines from Zeiss and Wenzel with 3D scanning systems

- Test chambers for steam jet tests

- Stone chip testing equipment

- Microscopy for coating thickness measurements

- Color and wave scan measuring devices

- Willing booth for visual color evaluations

Clear advantages through versatile testing technology – everything from a single source

LMS inspects components visually, materially and geometrically – this is one of our particular strengths. Through customized test setups and testing machines, we offer our customers everything as a one-stop shop when it comes to testing technology. Our locations and our test center in Esslingen offer many possibilities for validating products: From the phases of product development to series production or beyond. For example, our capabilities include a wide variety of environmental simulations, temperature, corrosion and aging tests. Our test centers also work with Design FMEA as well as DVP&R (Design Verification Plan and Reports).

By drawing on these capabilities, our customers have a distinct advantage: with us as their partner, they can use an end-to-end package for component validation, covering around 95 percent of the tests required in the sampling process.

Our services

Our quality

Strong quality processes enable high-end products

LMS is committed to robust quality processes. It uses advanced software solutions to effectively and efficiently realize all requirements of a functioning quality management system. CAQ AG is at our side as a central, long-standing partner.

We use CAQ software’s complaint management, document management, gauge management, and other modules at all of our locations. For our supplier management, the “Supplier Data Base,” we work together with Jawa Management Software from Austria. Our suppliers benefit from this. They have the possibility to evaluate new inquiries, upload certificates and audits, secure product development processes with maturity levels, and process complaints.

Dynamic product audits, full process audits and cross-system audits at our facilities and those of our suppliers complement the software systems. On this basis, we ensure that our quality is assured at all times and at every point in the process.