State-of-the-art software meets the highest standards of quality and design

Whether for individual add-on parts or for complex assemblies in the exterior: LMS advises customers on all their questions. We know how to develop large plastic components and have experience with various surface treatments, modules or material combinations.

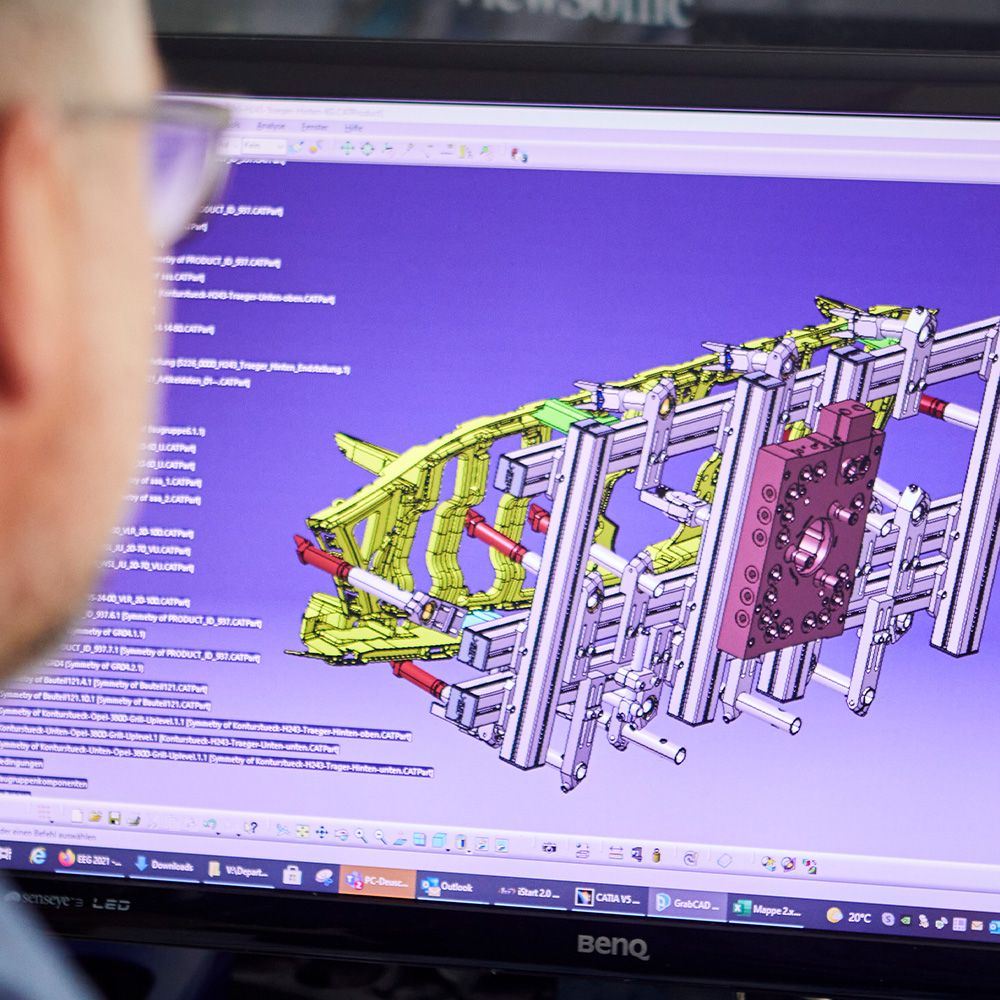

Thanks to state-of-the-art software, we implement our customers’ ideas quickly and with a lot of flexibility. With the help of CAD and CAE systems, prototype construction and 3D printing, we meet the highest standards of quality and design. Our experienced engineers and technicians accompany the entire process – from development to series production.

Our technology

Our services

Experience from complex processes enables comprehensive services

LMS offers its customers extensive expertise in Siemens NX and Catia. We also smoothly integrate the data into the entire process chain. In addition, we can offer static as well as dynamic or NVH safeguarding – our tools Radioss, LS-Dyna, Nastran or Optistruct are used for this. To optimize products at an early stage and avoid warpage in injection molding, we have been using Moldex3D for many years.

Our customers benefit from our wide range of services and the experience we have gained in many complex projects. This benefits them, for example, when we support them in commissioning assembly and logistics centers or JIS/SILS resequencing processes.

Continuous quality analyses set standards and optimize products

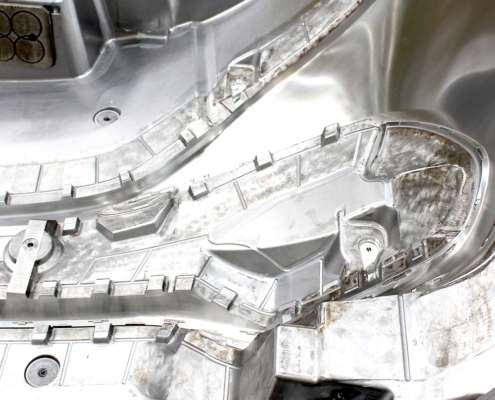

Continuous analysis processes are standard for LMS. In this way, we discover weak points at an early stage and can eliminate them as quickly as possible. When developing new products, we always maintain contact with internal quality assurance. Based on our CAE calculation, we also cover removal gripper simulations, for example. This means: We identify problem areas in advance, solve them proactively and incorporate solutions directly into the design.

One example of our quality testing in the injection molding segment is mold flow analysis: This allows us to test the exact behavior of the incoming material. For example, we can estimate the material behavior under the influence of heat and thus prevent surfaces from warping.

Our quality

Our innovations

Proactive analyses and the greatest possible flexibility are important for new ideas

With the help of its own processes and an internal sample and prototype construction, LMS ensures lasting flexibility. Methods such as 3D printing also make it possible to produce ideally customized solutions in a wide variety of processes. New ideas can also be implemented efficiently at any time.

On the basis of ongoing analyses, we are also constantly on the lookout for possible weak points and proactively eliminate them. For example, we use our 3D production layout to identify in advance where difficulties may arise. Against this backdrop, we optimize our process in a targeted manner in exactly the right places.